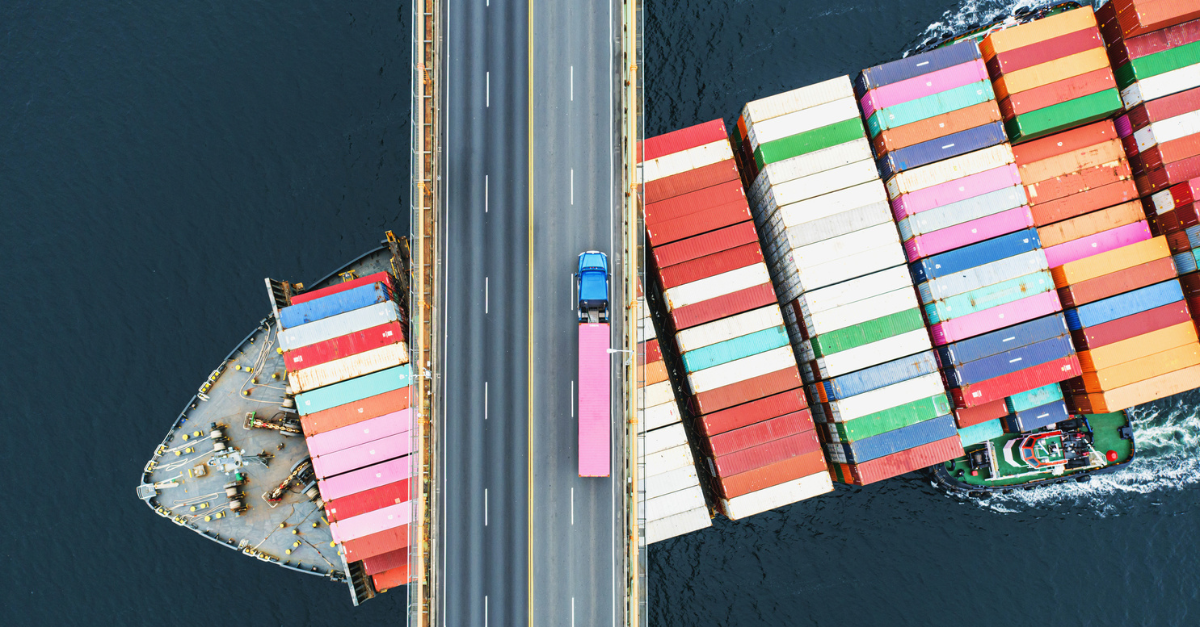

Digital technologies and the explosion of Internet of Things (IoT) have not only revolutionized business processes in just about every industry, but our daily lives as well. In light of the multilayered impacts of the pandemic, virtually every industry has turned to the combined benefits of mobile computing, cloud services, and IoT to navigate communication, supply logistics, and demand challenges.

Prior to the pandemic, digital technologies and automation had gained significant momentum in the manufacturing sector, however supply chain processes still relied heavily upon human interactions and labor. The chaos of a global catastrophe radically upended domestic and international supply chains and the labor force they relied upon. Businesses that were able to leverage IoT data-rich devices fared far better than those who lagged behind.

IoT devices worldwide are projected to amount to 30.9 billion units by 2025, a sharp jump from the 16.4 billion unit estimate of 2022. These “connected things” have become crucial for managing supply chain disruptions, labor shortages and growing logistics volumes. IoT devices store and share data that feeds a supply chain ecosystem to become more transparent, efficient, accurate and resilient for real-time management and mitigation.

IoT is revolutionizing every facet of supply chain management

Integrated digital solutions that seamlessly connect all parts of the supply chain journey within a single interface have forever changed the face of global commerce. IoT and Electronic Data Interchange (EDI) solutions are equipping supply chain ecosystems with real-time visibility, expediency, and accuracy.

EDI software is a core component of today’s successful supply chain operations, enabling quick and secure electronic transactions that replace error-prone paper-based interactions. Electronic business document exchanges between trading partners can accurately and expeditiously handle bills of lading, inventory lists, shipping authorizations and customs documents, to name a few. Manual processes that could take days and weeks are reduced to minutes, and human error is eliminated.

The deployment of IoT in supply chain networks is enabling a number of crucial advancements and benefits for superior inventory management and freight forwarding including:

-

Inventory management and forecasting – IoT sensors track inventory positions, supply levels, locations, and conditions in real-time. The continual flow of IoT data enables more accurate predictive analytics and forecasting for actionable decisions and elimination of material waste. Consumer demand can be predicted from 6-12 months in advance.

-

Shipping and tracking of assets – Manual processes are becoming obsolete as IoT technology delivers greater efficiencies through the use of intuitive trackers and beacons, like Radio Frequency Identification (RFID) tags and global SIMS to locate, identify, and determine asset status. Sensors and monitors that measure changes in temperature, humidity, time, and other variables accurately gauge asset integrity. Predictive smart sensors trigger alerts for cargo conditions, as well as provide data that allows the adjustment of freight delivery schedules as weather and traffic conditions change.

-

Supply chain visibility – IoT solutions are delivering the capacity for supply chain transparency across all parties. IoT provides real-time continual access from warehouse inventory levels and storage, to shipping and tracking, all the way to last mile delivery. End-to-end freight visibility ensures asset integrity and adherence to planning, while reducing the potential for theft and loss as materials and merchandise journey to their point of delivery. Loss prevention, waste reduction, and streamlining logistics all contribute to reducing cost and orchestrating superior service, product delivery and security for customers.

-

Fleet management and predictive maintenance – Cloud apps and IoT devices monitor equipment health in real-time, providing alerts for malfunctions and predictive analytics for maintenance. Rather than following traditional maintenance schedules that can cause wasteful downtime, IoT sensors alert only when assessments and repairs are needed and catch problems human counterparts might miss.

-

The all-important ‘last mile’ delivery – Online consumerism has soared, forcing e-commerce to rapidly scale last mile delivery practices. Globally, last mile operations account for around 40+ percent of the entire supply chain cost. Logistics optimization and investment in the right dispatch automation software and IoT solutions is an imperative for minimizing expenses and improving workflows in last mile delivery operations. The use of GPS and geofencing can optimize routes through real-time traffic analytics and save on time and fuel costs. As supply chain operations continue to evolve with digitalization, expedited last mile delivery innovations will increase with the use of smartphones, drones, and AI robotics.

Logistics companies are capitalizing on IoT benefits

IoT systems have become more attractive to logistics operators than ever before. Logistic giants like DHL and UPS are leaders in promoting the innovation and use cases for digital apps and devices for a holistic supply chain approach.

UPS, which has already greatly expanded its use of IoT sensors on trailers and transports for location of assets, security awareness and last-mile GPS and geofencing data, is applying digital logistics to a new division - UPS Premier. A healthcare-oriented service, it integrates next-generation tracking and sensor technologies to improve the accuracy and security of medical and healthcare products. Urgent medical packages are equipped with highly intuitive sensors for assessment of product conditions, quality, and safe delivery. IoT connected solutions can vastly improve the availability, transport, efficacy and safety of medicines, vaccines, and myriad health products in ways never previously imagined.

The future applications for IoT in supply chain and freight forwarding are seemingly endless, going well beyond the constraints of human capacity. As it evolves, companies must be cognizant of heightened cybersecurity risks and establish security best practices. Supply chains now and in the future will need to integrate intelligent technology to ensure security measures to mitigate targeted disruptions, as well as protect against counterfeit and fraudulent trades.

Interested in reading more about how the IoT can secure the industrial market, click here to read our white paper.